|

|

| |

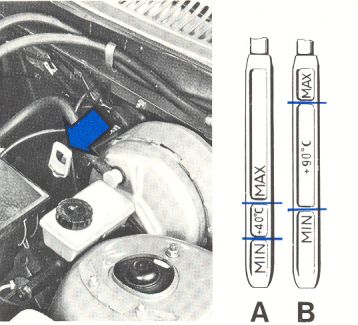

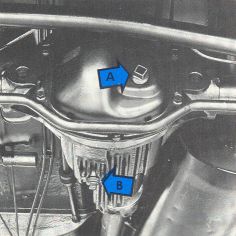

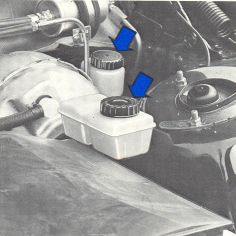

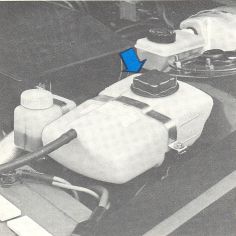

Checking oil level |

|

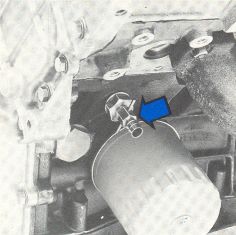

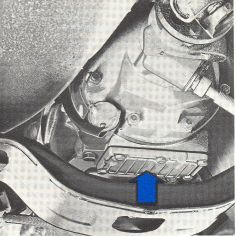

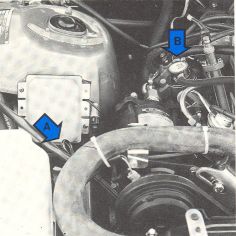

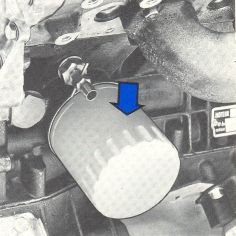

Changing oil filter |

|

The oil level should be checked each time the fuel tank is refilled Be sure the oil level is maintened between the upper and lower marks on the dipstick. Low oil level can cause internal damage to the engine and overfilling can result in high oil consumption. The distance in high oil consumption. The distance between the dipstick marks repre- sents approx. 2 US qts=2 liters/1.8 lmp.qts. of oil. |

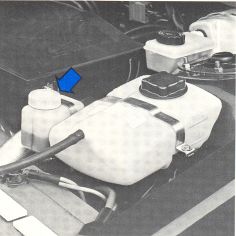

At temperatures below 0°F (-18°C), multi- grade oil SAE 5W-20 or SAE 5W-30 is recom- mended. However, this oil should not be used when the temperature is continuously above 32°F (0°C). Driving under adverse conditions such as high ambient temperatures, trailer hauling, hill climbing, driving long distances at high speeds, extended periods of idling, low speed operation or short trip operation at free- zing temperatures may require oil and filter changes more frequently (every third month). Drain the oil after driving while it is still hot. |

Replace the oil filter at every change. If the oil filter is changed separately, ½ US qt. =0.5 liter/½ lmp. qt. of oil should be added. |